Understanding Gas Bottle Boxes

What Are Gas Bottle Boxes?

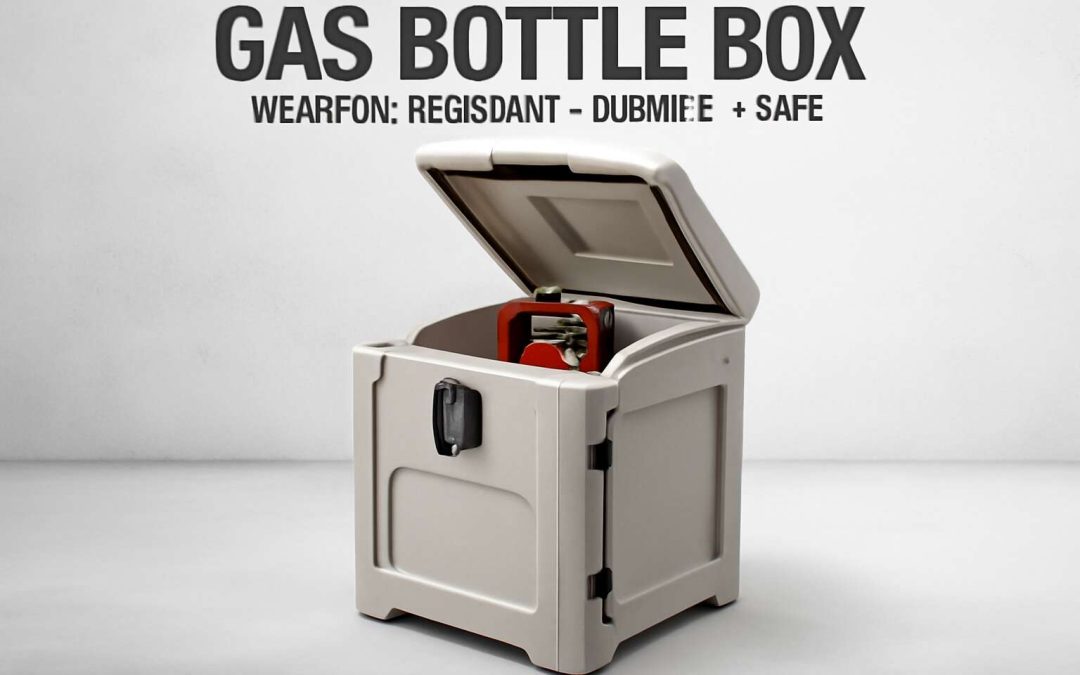

In the realm of industrial safety and transportation, few innovations are as vital yet overlooked as the humble gas bottle box. These sturdy enclosures serve as silent guardians, ensuring that hazardous gases are contained securely while facilitating smooth handling and storage. A gas bottle box is not merely a container; it’s a fortress designed to withstand the rigors of transportation, preventing accidents and damage that could have catastrophic consequences.

Understanding gas bottle boxes involves appreciating their intricate design and purpose. They are crafted from durable materials, often reinforced with protective coatings, to endure the weight and potential impact of gas bottles. The primary goal is to safeguard both the environment and personnel from leaks or ruptures that can occur during transit or storage. In South Africa, where safety regulations are stringent, these boxes are indispensable for industries relying on gas cylinders for their daily operations.

- Enhanced safety during transport

- Protection against environmental elements

- Facilitation of efficient storage and handling

By encapsulating gas bottles within these specialized boxes, companies not only comply with safety standards but also uphold a commitment to responsible stewardship of hazardous materials. Whether for industrial, commercial, or domestic use, understanding the vital role of a gas bottle box reveals a world where safety and efficiency intertwine seamlessly.

Types of Gas Bottle Boxes

Understanding the various types of gas bottle boxes reveals a fascinating intersection of safety, engineering, and practicality. In South Africa’s dynamic industrial landscape, selecting the appropriate gas bottle box is crucial for ensuring compliance and safeguarding personnel and the environment. These boxes come in different designs tailored to specific needs, from standard models for small gas cylinders to heavy-duty variants built for bulk storage.

Among the most common are the protective gas bottle boxes, which feature reinforced walls and impact-resistant materials to absorb shocks during transit. Then, there are industrial-grade gas bottle boxes, designed to withstand harsh environmental conditions, such as extreme temperatures and exposure to moisture. For specialized applications, customized gas bottle boxes offer bespoke solutions, incorporating features like ventilation systems or secure locking mechanisms.

To navigate these options effectively, consider the following aspects:

- Material strength and durability

- Compatibility with specific gas cylinder sizes

- Regulatory compliance and safety standards

Ultimately, choosing the right gas bottle box is more than a matter of convenience; it’s a fundamental pillar of responsible handling and transportation of hazardous gases. Each type plays a vital role in creating a safer, more efficient industrial environment, especially in regions where safety regulations are strict and enforcement is rigorous.

Materials Used in Manufacturing

In the world of gas bottle safety, the materials used in manufacturing a gas bottle box are nothing short of the unsung heroes. They must strike a delicate balance between robustness and practicality, ensuring the cylinder remains shielded from the unpredictable whims of the environment. South Africa’s industrial sectors demand materials that can endure not only the weight of the gas but also the relentless grip of exposure to moisture, extreme heat, or sudden impacts.

Commonly, these boxes are crafted from high-strength steel or durable plastics. Steel, with its formidable resilience, provides an impenetrable barrier against physical shocks and accidental punctures. Meanwhile, advanced polymers offer lightweight advantages and resistance to corrosion, making them ideal for long-term outdoor storage. To meet diverse needs, manufacturers often incorporate layered constructions or composite materials, which enhance safety and longevity.

When selecting a gas bottle box, it’s vital to consider the material’s ability to meet strict safety standards. The ideal gas bottle box for South Africa’s rugged terrains and industrial demands combines strength, flexibility, and regulatory compliance—proving that, in this arena, material science truly is the backbone of safety. Whether reinforced for heavy-duty use or tailored for specialized applications, the choice of material ensures each gas bottle remains as secure as a secret in a vault—impressive, resilient, and utterly essential.

Benefits of Using Gas Bottle Boxes

Enhanced Safety and Security

Safety isn’t just a buzzword—it’s a necessity, especially when it comes to handling gas bottles. Using a gas bottle box significantly enhances safety and security, reducing the risk of accidents and leaks. These sturdy enclosures act as a first line of defense, containing potential hazards and preventing unintended contact with flames or sparks.

In environments where gas bottles are frequent, such as industrial sites or residential areas in South Africa, the importance of secure storage cannot be overstated. Gas bottle boxes provide peace of mind by shielding the bottles from external threats like vandalism, weather damage, or accidental impacts. They also help contain any leaks, limiting exposure to harmful gases and protecting workers and residents alike.

For added security, consider the following features of a high-quality gas bottle box:

- Lockable doors to prevent unauthorized access

- Ventilation systems to disperse residual gases safely

- Robust construction materials to withstand harsh conditions

Protection During Transportation

Transporting gas bottles isn’t just about getting from point A to B—it’s a journey fraught with potential hazards that must be managed with meticulous care. A well-designed gas bottle box transforms this process from perilous to secure, acting as an invisible guardian that shields both the cargo and those around it. In South Africa’s bustling industrial hubs and serene residential streets, the importance of protection during transportation cannot be overstated.

Imagine a sturdy, weather-resistant enclosure that not only contains leaks but also absorbs the shock of sudden impacts. That’s the magic of a high-quality gas bottle box. It provides an extra layer of security, ensuring that even in the chaos of transit, the integrity of the gas bottle remains uncompromised. For those navigating rugged terrains or congested city roads, these boxes are an essential safeguard.

Moreover, the benefits extend beyond safety. Gas bottle boxes streamline handling procedures, making loading and unloading more efficient. They also help prevent accidental contact with flames or sparks, significantly reducing the risk of ignition. This combination of protection and practicality underscores why gas bottle boxes are indispensable for safe, reliable transportation across South Africa’s diverse environments.

Storage Efficiency and Space Optimization

In a landscape where space is often at a premium—especially within South Africa’s bustling industrial zones—the art of storage becomes an exercise in finesse. Enter the humble yet mighty gas bottle box, a marvel of space optimization that transforms chaos into order. By stacking and organizing gas bottles efficiently, these boxes reduce clutter and maximize storage capacity, turning cramped yards into models of spatial harmony.

With the right gas bottle box, handling becomes a breeze. The streamlined design allows for easy stacking and secure placement, which means fewer trips and less fuss when it’s time to move or access bottles. For businesses and homeowners alike, this translates into tangible time savings and a more orderly environment. Think of it as a secret weapon against the clutter monster—an elegant solution that quietly champions efficiency.

- Optimized storage capacity

- Reduced risk of accidental damage

- Easier handling and access

Ultimately, investing in a quality gas bottle box isn’t just about safety—it’s about making every square meter count, whether you’re managing a sprawling industrial warehouse or a cozy residential garden. Space, after all, is the ultimate luxury—and the gas bottle box is its discreet, dependable guardian.

Customizability and Branding Opportunities

In a landscape where branding speaks louder than words, the benefits of using a gas bottle box extend far beyond mere protection. Customizability transforms a standard gas bottle box into a powerful branding tool, allowing companies to showcase their logo, motto, or unique color schemes. This not only elevates brand recognition but also fosters trust among clients who associate quality with visual consistency.

Moreover, a well-designed gas bottle box can be tailored to meet specific needs. Whether it’s reinforced panels for added durability or integrated handles for easier handling, customization ensures every box serves its purpose flawlessly. For businesses aiming to stand out, this level of personalization turns an ordinary storage solution into a memorable impression.

Additionally, branding opportunities abound. Custom printing on a gas bottle box can include safety instructions, company contact details, or promotional messages—making each unit a mobile advertisement. Such strategic branding amplifies visibility and reinforces professionalism, ultimately turning a simple storage container into a subtle yet impactful marketing asset.

Key Features to Consider When Choosing a Gas Bottle Box

Durability and Material Strength

When selecting a gas bottle box, durability isn’t just a feature—it’s an absolute necessity. South African industries demand resilient solutions that withstand harsh conditions, ensuring safety and longevity. The material strength of a gas bottle box directly correlates with its ability to absorb shocks, resist corrosion, and endure fluctuating temperatures. A robust gas bottle box acts as a formidable shield, preventing accidents and preserving the integrity of the stored gas.

Consider the environmental factors at play—dust, moisture, and rough handling are common challenges. High-quality gas bottle boxes often incorporate reinforced panels or innovative composite materials that elevate their durability. This isn’t just about protecting the bottle; it’s about safeguarding lives and assets. For a truly reliable choice, look for gas bottle boxes that combine strength with lightweight design, facilitating easier handling without compromising safety.

Ventilation and Safety Features

When choosing a gas bottle box, ventilation and safety features are paramount to ensure optimal protection and compliance with safety standards. Proper airflow prevents the buildup of dangerous gases, reducing the risk of explosions or leaks. Ventilation panels or vents should be strategically positioned to facilitate continuous air exchange without compromising the box’s structural integrity.

In addition to ventilation, safety features such as lockable lids, reinforced handles, and secure fastening mechanisms are vital. These elements not only deter unauthorized access but also enhance stability during handling and storage. An effective gas bottle box often incorporates multiple safety layers, including shock-absorbing padding and corrosion-resistant coatings, which collectively create a formidable barrier against environmental hazards.

For those prioritizing safety, consider gas bottle boxes with integrated safety features like pressure relief valves or alarms that alert users to potential issues. Such innovations elevate the standard of safety, transforming a simple protective casing into a comprehensive safety system. Remember, in the realm of gas storage, safety isn’t just a feature—it’s the foundation of responsible handling and risk mitigation.

Size and Fit for Different Gas Bottles

Choosing the right gas bottle box isn’t just about size; it’s about ensuring a perfect fit that enhances safety and efficiency. A poorly fitted box can lead to unnecessary movement, increasing the risk of leaks or damage. Accurate dimensions are crucial—measure your gas bottles carefully and select a gas bottle box that offers a snug yet accessible fit.

In South Africa, where safety standards are becoming more stringent, it’s essential to prioritize size compatibility. An ill-fitting gas bottle box can compromise ventilation and safety features, defeating the purpose of these protective enclosures. When selecting a gas bottle box, consider the variety of gas bottle sizes you handle regularly. Opt for models that accommodate your largest bottles comfortably while still securing smaller ones tightly.

- Assess the dimensions of your gas bottles

- Choose a gas bottle box with adjustable or customizable features

- Ensure the box provides enough clearance for safe handling and ventilation

Remember, in the realm of gas storage, a well-chosen gas bottle box is vital for both safety and operational efficiency—making size and fit the foundation of responsible handling.

Ease of Assembly and Reusability

When it comes to selecting a gas bottle box, ease of assembly and reusability are often overlooked yet profoundly impactful features. A well-designed gas bottle box should not only be straightforward to assemble but also resilient enough to withstand multiple uses without compromising safety or integrity. This dual functionality ensures that your investment remains cost-effective while maintaining high safety standards—an essential consideration in South Africa’s evolving safety landscape.

Opt for a gas bottle box with intuitive locking mechanisms and minimal tools required for assembly. This simplifies the process, reduces downtime, and minimizes the risk of improper setup. Reusability, on the other hand, hinges on durable materials and thoughtful construction, allowing the box to serve multiple cycles of storage or transport without deterioration. When choosing a gas bottle box that balances ease of assembly with durability, you create a safer, more efficient environment for handling gas bottles—protecting both your personnel and your assets.

Environmental Impact and Recyclability

In a world where sustainability is no longer a buzzword but a mandate, the environmental impact and recyclability of your gas bottle box deserve a standing ovation. With South Africa’s burgeoning emphasis on eco-conscious practices, selecting a gas bottle box that champions recyclability not only aligns with green ideals but also keeps your operations compliant and community-friendly. A well-crafted gas bottle box made from biodegradable or recycled materials can significantly reduce your carbon footprint—because even heavy-duty safety gear should have a conscience.

Moreover, look for options that are designed with the environment in mind. Features such as eco-friendly materials, minimal packaging, and options for reuse are more than just trendy—they’re essential. When your gas bottle box can be recycled at the end of its lifecycle, it transforms from mere storage to a statement of sustainability. After all, why settle for a box that only protects your gas bottles today when it can also help preserve the planet tomorrow?

Design and Customization Options

Branding and Logo Placement

When it comes to designing a gas bottle box, innovation and flexibility are key to meeting diverse needs. A thoughtfully crafted gas bottle box should seamlessly blend functionality with aesthetic appeal, ensuring safety while promoting brand visibility. Customization options allow businesses to tailor their packaging, transforming a simple container into a powerful marketing tool. From vibrant color schemes to premium finishes, the possibilities for branding and logo placement are virtually limitless, helping your brand stand out in a competitive market.

Effective branding on a gas bottle box not only enhances recognition but also communicates professionalism and quality. Incorporating your logo prominently, whether through embossing, printing, or decals, can elevate your product’s perceived value. For a cohesive look, consider the following branding strategies:

- Strategic logo placement on the lid or sides for maximum visibility

- Use of high-quality printing techniques to ensure durability

- Incorporation of brand colors that resonate with your identity

Ultimately, a well-designed gas bottle box combines safety, durability, and visual appeal, ensuring your product is protected and memorable on every shelf and during transport. Customization options make it possible to craft a packaging solution that truly reflects your brand’s essence, establishing trust and recognition with every gas cylinder delivered.

Color Schemes and Aesthetic Appeal

In a marketplace saturated with competition, the allure of a meticulously crafted gas bottle box can make all the difference. Color schemes serve as the visual heartbeat of your packaging—vivid hues that evoke trust, safety, and professionalism. Imagine a palette that seamlessly aligns with your brand’s ethos, transforming each gas bottle box into a striking emblem of reliability and quality. The aesthetic appeal isn’t merely superficial; it’s a strategic tool that captivates the eye and leaves a lasting impression.

Customization options elevate a simple gas bottle box into a canvas of expression. From matte finishes that whisper sophistication to glossy coatings that shimmer under the light, the choices are boundless. Incorporating your brand’s signature colors or unique design elements into the gas bottle box can forge an emotional connection with your customers, forging trust through visual harmony. In South Africa’s vibrant market, these tailored touches help your product stand out amidst the bustling shelves and transport routes, making safety and style collide in perfect harmony.

Additional Safety Markings and Labels

When it comes to a gas bottle box, design and customization are the secret sauce that transforms a mere container into a safety statement. Imagine a sturdy, well-crafted gas bottle box that not only protects but also proudly displays your brand’s personality. Customization options allow you to incorporate eye-catching graphics, bold typography, or even playful patterns that make your product stand out on South African shelves. A thoughtfully designed gas bottle box isn’t just about looks—it’s about creating a memorable impression that builds trust with customers.

But aesthetics are only part of the story. Additional safety markings and labels are crucial—think of them as the gas bottle box’s safety gloves and warning signs. Clear, durable markings indicating pressure ratings, hazard symbols, and handling instructions ensure that everyone along the supply chain is aware of the risks. For added peace of mind, consider including:

- Flammable warning labels

- Handling instructions

- Emergency contact details

These safety features elevate the gas bottle box from a simple shipping solution to a responsible and compliant packaging choice, especially vital in South Africa’s diverse market landscape. With the right combination of design innovation and safety markings, your gas bottle box will not only protect your product but also reinforce your brand’s commitment to safety and quality.

Manufacturing and Supply of Gas Bottle Boxes

Leading Manufacturers and Suppliers

In the bustling landscape of South Africa’s industrial sector, the manufacturing and supply of gas bottle boxes stand as a testament to innovation and resilience. Leading manufacturers have perfected the art of crafting durable, environmentally friendly gas bottle boxes that meet rigorous safety standards while also catering to the aesthetic demands of modern businesses. These suppliers understand that a well-designed gas bottle box is more than just packaging—it is a symbol of reliability and trust.

The most reputable companies often adopt a meticulous approach, integrating cutting-edge materials and sustainable practices to produce high-quality gas bottle boxes. They emphasize not only strength and safety but also seamless customization options, allowing brands to showcase their identity boldly. Whether for transportation, storage, or display, these top-tier manufacturers ensure each gas bottle box is tailored for optimal fit, enhanced security, and eco-conscious reuse. In a market driven by both safety and style, the supply chain’s ability to deliver consistent, innovative solutions cements their role as industry leaders.

Order Quantities and Lead Times

In the dynamic realm of gas bottle box manufacturing, order quantities and lead times are the heartbeat of seamless supply chains. For South African industries, the rhythm of production must align with the urgency of demand, where prompt delivery can mean the difference between operational continuity and costly delays. Leading manufacturers often operate on a flexible scale, accommodating everything from small custom orders to large-volume shipments with precision and reliability.

Typically, small to medium enterprises might place orders ranging from 500 to 5,000 units, with lead times stretching from 2 to 4 weeks. For bulk orders, especially those tailored for industrial use, the timeline can extend to 6 to 8 weeks, depending on complexity and customization. To streamline the process, many suppliers have adopted a systematic approach:

- Initial consultation to determine specifications and quantities

- Design and prototype approval

- Mass production and quality assurance

- Efficient logistics to ensure timely delivery

Such meticulous planning ensures that the production of gas bottle boxes remains an orchestrated dance of efficiency, delivering on promises of safety, durability, and sustainability. As demand surges across South Africa’s expanding energy and manufacturing sectors, these manufacturers stand ready to meet expectations with both agility and unwavering quality, turning every gas bottle box into a symbol of trust and resilience.

Pricing and Cost Factors

In the shadowed corridors of industrial commerce, the manufacturing and supply of gas bottle boxes are woven with an intricate dance of cost factors and strategic pricing. These vessels of safety and protection must be crafted with precision, for they serve as the silent guardians during transportation and storage. The cost of a gas bottle box hinges on several elements—material selection, design complexity, and order volume each cast their influence like unseen specters shaping the final price.

For smaller enterprises in South Africa, pricing might be more flexible, yet bulk orders often unlock economies of scale, reducing the cost per unit. Leading manufacturers often employ a tiered pricing model, where larger orders—say, 10,000 units or more—entail a significantly lower cost, thanks to optimized production runs and streamlined logistics. This strategic approach ensures that each gas bottle box embodies not only durability but also economic efficiency, vital in a competitive landscape.

Factors such as raw material prices, labor costs, and customization demands all swirl together to determine the final cost. Some suppliers may also factor in the expenses related to safety markings, branding, or special ventilation features, which can influence the overall expenditure. Navigating this labyrinth of pricing requires a keen eye and a deep understanding of the market’s ebb and flow—after all, in the realm of gas bottle boxes, every rand must be meticulously accounted for to uphold safety without sacrificing quality.

Regulations and Safety Standards

Compliance Requirements

Ensuring compliance with regulations and safety standards for gas bottle boxes is not just a legal requirement; it’s a moral obligation that safeguards lives and property. In South Africa, strict adherence to these standards is essential for manufacturers and distributors alike. Regulatory frameworks demand that gas bottle boxes meet specific safety criteria, including durability, proper ventilation, and clear safety markings. These measures are designed to prevent accidents during transportation and storage, especially given the volatile nature of compressed gases.

Failure to comply can result in severe penalties, but more critically, it endangers everyone involved. To streamline compliance, many companies follow a checklist such as:

- Material strength standards

- Proper labeling with safety warnings

- Secure locking mechanisms for transport

- Ventilation features to prevent gas accumulation

Understanding and implementing these safety standards transforms a simple gas bottle box into a fortress of protection, ensuring peace of mind from the manufacturing plant to the end-user’s doorstep. The importance of regulatory compliance cannot be overstated—it’s the invisible shield that keeps everyone safe in a world where gas leaks and mishaps can be catastrophic.

Industry Standards to Follow

Regulations and safety standards are the backbone of a reliable gas bottle box industry. In South Africa, strict adherence to these standards isn’t optional—it’s vital for preventing accidents and ensuring safe handling from factory to end-user. Regulatory bodies specify precise safety criteria, including material durability, ventilation, and clear safety markings, to mitigate the risks associated with compressed gases.

Manufacturers must follow a comprehensive set of industry standards to ensure compliance. These include:

- Material strength standards to withstand impacts and environmental stress

- Proper labeling with safety warnings to alert handlers of hazards

- Secure locking mechanisms for safe transport and storage

- Ventilation features to prevent gas buildup and reduce explosion risk

Meeting these regulations transforms a basic gas bottle box into a critical safety device. It’s not just about legal compliance; it’s about protecting lives and property. The importance of these safety standards cannot be overstated—they are the invisible shield guarding everyone involved in the supply chain.

Ensuring Safety During Handling and Storage

Safety during the handling and storage of compressed gases hinges on more than just careful procedures—it depends on the integrity of the gas bottle box itself. In South Africa, regulatory standards set the bar high, demanding that every gas bottle box adhere to strict safety criteria. These standards act as an invisible shield, safeguarding workers, transport operators, and end-users from potential hazards.

A well-designed gas bottle box incorporates features like secure locking mechanisms, impact-resistant materials, and effective ventilation. Ventilation is particularly crucial, as it prevents gas buildup—an often overlooked risk that can lead to dangerous explosions. Regulatory bodies specify these safety features to ensure that each gas bottle box not only complies with legal requirements but also provides peace of mind during every stage of handling and storage.

- Material strength standards guarantee that the gas bottle box withstands impacts and environmental stresses.

- Clear safety markings alert handlers to potential hazards at a glance.

- Proper locking mechanisms maintain secure containment during transport and storage.

In essence, these safety standards elevate a simple gas bottle box into a vital component of the safety chain—protecting lives, property, and the environment with every use. The importance of compliance cannot be overstated, as it transforms the ordinary into a formidable barrier against unforeseen accidents.

Tips for Maintaining and Recycling Gas Bottle Boxes

Proper Handling and Storage Tips

Proper handling and storage of a gas bottle box is crucial to maintaining safety and extending its lifespan. When stacking or storing gas bottle boxes, always ensure they are placed on a flat, stable surface to prevent accidental tipping or damage. It’s essential to keep these boxes in a well-ventilated area, away from direct sunlight or sources of heat, to avoid material degradation.

To keep your gas bottle box in prime condition, consider implementing a regular inspection routine. Look for signs of wear, tears, or compromised safety markings. If damage is detected, replace the box promptly to preserve safety standards.

For recycling, many gas bottle boxes are made from recyclable materials. A simple step is to disassemble the box and remove any labels or safety markings before recycling. This ensures the materials can be processed efficiently, reducing environmental impact.

- Store gas bottle boxes upright to maintain structural integrity.

- Avoid stacking boxes too high to prevent collapse or damage.

- Keep a safe distance from heat sources and chemicals.

Handling a gas bottle box with care not only ensures safety but also contributes to a more sustainable approach to managing these essential safety containers.

Recycling and Disposal Guidelines

Proper maintenance and responsible recycling of a gas bottle box not only extend its lifespan but also play a vital role in ensuring safety and environmental sustainability. When it comes to recycling, the first step is to disassemble the gas bottle box carefully, removing any labels or safety markings that may hinder the recycling process. This simple act ensures that the recyclable materials are processed efficiently, reducing waste and conserving resources. For those looking to dispose of gas bottle boxes responsibly, many materials used are indeed recyclable, aligning with eco-friendly practices prevalent in South Africa.

To keep your gas bottle box in peak condition, regular inspections are key. Check for any signs of wear, tears, or fading safety markings—damage that could compromise safety standards. If any issues are detected, replacing the box promptly is essential. Proper storage techniques, such as storing gas bottle boxes upright and on stable, flat surfaces, help maintain their structural integrity and prevent accidental collapse. Additionally, storing these boxes away from heat sources and chemicals safeguards against deterioration and potential hazards.

- Disassemble the gas bottle box carefully, removing labels and safety markings.

- Inspect regularly for signs of wear or damage.

- Store upright on a flat, stable surface in a well-ventilated area.

- Avoid stacking too high to prevent collapse or damage.

By adhering to these recycling and disposal guidelines, you contribute not only to a safer environment but also uphold the integrity of safety standards for gas bottle storage and handling. Every responsible action counts in fostering a culture of safety and environmental consciousness in South Africa’s dynamic industrial landscape.

Extending the Life of the Boxes

Keeping your gas bottle box in top shape isn’t just about safety—it’s about squeezing every last drop of value from your investment. Regular inspections are the secret weapon here. Look out for wear and tear, fading safety markings, or any sign that your trusty box might be on its last legs. When damage is detected, don’t delay—swap it out before safety standards are compromised. A well-maintained gas bottle box can serve you longer, saving you money and ensuring compliance with South Africa’s strict safety regulations.

To prolong the life of your gas bottle box, proper storage is non-negotiable. Store it upright on a flat, stable surface in a well-ventilated area—think of it as giving your box a VIP treatment. Avoid stacking multiple boxes too high; the risk of collapse and damage is just not worth it. Additionally, keeping the gas bottle box away from heat sources and chemicals prevents deterioration and potential hazards. Remember, a little TLC goes a long way in safeguarding both your personnel and the environment.

When it’s time to recycle, disassemble your gas bottle box carefully, removing labels and safety markings that might hinder the recycling process. This small act ensures that recyclable materials are processed efficiently, reducing waste in South Africa’s landfills. And if you’re looking to extend the box’s usability, consider repurposing or reusing it for storage or other practical uses—an eco-friendly choice that also saves you a few rand. After all, responsible handling and recycling of a gas bottle box are essential steps towards a safer, greener industrial landscape.

Where to Purchase Quality Gas Bottle Boxes

Online Retailers and Marketplaces

Looking to purchase a reliable gas bottle box online? The good news is, South Africa’s bustling digital marketplace offers a treasure trove of options for quality gas bottle boxes. From dedicated industrial suppliers to general online retailers, the choices are plentiful. Online marketplaces like Takealot and Builders Warehouse provide an easy-to-navigate experience, often featuring customer reviews that serve as a virtual handshake before you commit.

For those seeking bespoke solutions, specialized manufacturers often list their products on their own websites or through B2B platforms such as Alibaba South Africa. These sources typically offer a variety of sizes and custom branding options, ensuring your gas bottle box isn’t just functional but also a marketing tool.

Here’s what you should look for when shopping online:

- Product specifications and safety features

- Customer reviews and ratings

- Availability of customizations and branding options

- Competitive pricing and delivery timelines

With so many options, finding the perfect gas bottle box online is easier than ever — just remember, the right one can make all the difference in safety, durability, and presentation.

Local Suppliers and Distributors

In the shadowed corridors of South Africa’s bustling industrial hubs, the quest for a reliable gas bottle box takes on an almost ritualistic significance. Local suppliers and distributors stand as gatekeepers to this vital component, offering a selection that balances safety, durability, and adaptability. These providers often operate from discreet warehouses or bustling storefronts, where the air hums with the promise of secure transport and storage. Navigating their offerings requires a keen eye for detail, as the right gas bottle box can mean the difference between catastrophe and peace of mind.

To streamline your search, consider focusing on trusted local distributors who specialize in industrial packaging solutions. Many of these suppliers list their products online, providing detailed specifications, safety features, and available customizations. Whether you need a standard gas bottle box or a bespoke design with your branding, these sources often cater to unique requirements. For example, some suppliers offer a variety of sizes and reinforced materials tailored to withstand South Africa’s demanding environments.

- Visit local industrial suppliers with a reputation for quality and safety.

- Explore their online catalogues for a diverse range of gas bottle boxes.

- Engage with distributors that offer customization and quick delivery options.

Choosing the right local partner ensures your gas bottle box isn’t just a container but a silent guardian—safeguarding your assets amidst the chaos of transportation and storage. It’s an investment in safety that echoes through every handling phase, making the search for quality local suppliers a journey worth undertaking.

Custom Box Design Services

When it comes to sourcing a quality gas bottle box, local suppliers and custom box design services are your best bet. South Africa boasts a network of reputable manufacturers and distributors dedicated to safety and durability. These providers often have online catalogues that showcase a variety of options tailored to different needs, making it easier to find the perfect fit for your gas bottles.

Many suppliers also offer bespoke design services, allowing you to incorporate your branding or specific safety features. This not only ensures compliance with industry standards but also enhances your company’s professional image. Whether you need a standard gas bottle box or a customized solution, exploring local options often results in quicker turnaround times and better support.

- Visit local industrial packaging suppliers known for their commitment to quality and safety.

- Browse their online platforms for detailed specifications and customization options.

- Engage with providers that offer quick delivery and flexible order quantities.

Choosing the right source for your gas bottle box means investing in a product that prioritizes safety, durability, and efficiency. Local distributors understand the unique challenges posed by South Africa’s environment, ensuring your gas bottle box is built to withstand demanding conditions. This approach guarantees your assets are well-protected during handling, storage, and transportation—an essential component in safeguarding your operations.